This product hasn’t been released yet, so I can’t go into to much detail here, but I will share what I can about this project!

The challenges of creating this system were:

- Sensing the amount of powder in a combined space

- Being able to dispense the powder out of a spout from the container without throwing off the level measurement

- Calibrating the sensor easily so that the operator of the machine can do it in an office environment

- Minimal cost impact

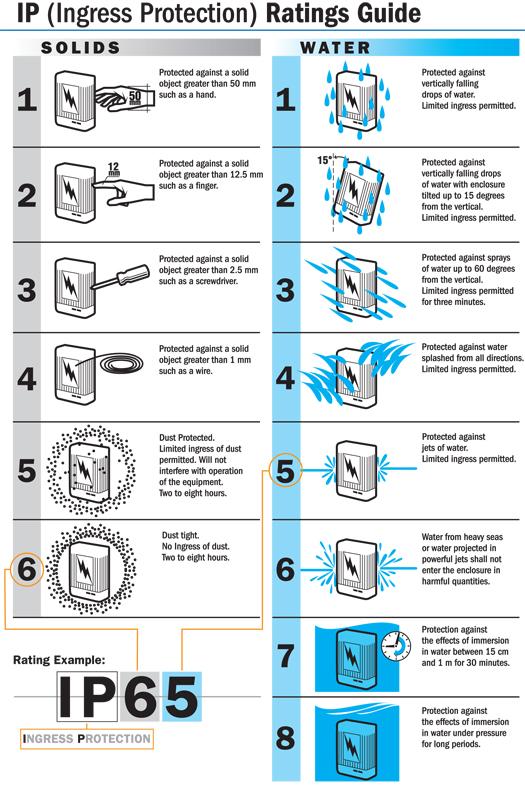

- Reliability in dusty and moist environment (IP65)

Our team tried a few methods for measuring the amount of powder in the bin.

We first used a rotary torque sensor to characterize the forces on the motor needed to turn an auger and dispense powder. Torque sensors are quite expensive, however. This method at least showed the correlation between amount of powder and resistance on the motor shaft.

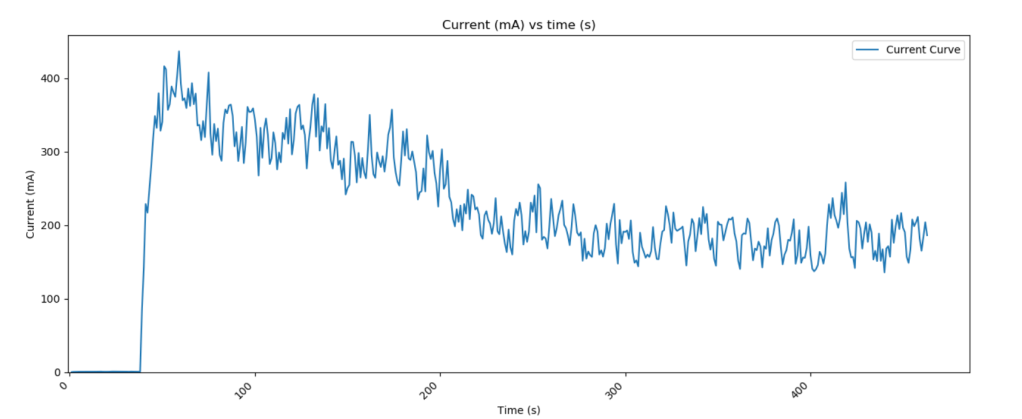

With the knowledge that current and torque are related, we considered using a current sensor on the motor to correlate the two. This was difficult for two reasons:

- There was a lot of noise in the current circuit

- You can only measure the “level” of powder, or resistance to turning, while the motor is moving. This is not optimal, as the powder in the machine is in a static state most of the time.

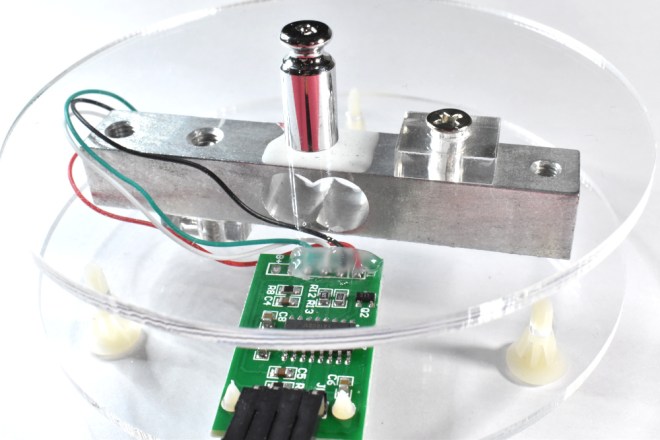

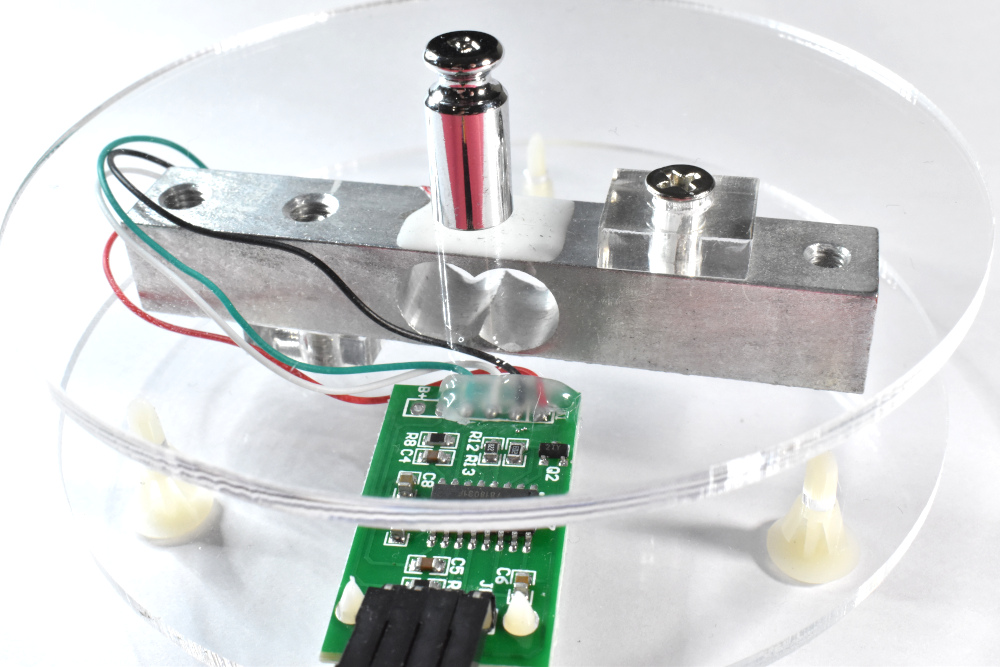

We decided to next try a load cell sensor, which are reliable, sensitive, and can be found for cheap:

The user sees an alert on the UI when the powder is running low. This also prevents downstream adverse effects of not having powder delivered.