A quick comment about this website: Any projects I worked on as an employee of a company may involve information I can’t share publicly. Please send me a message if you’d like to know more!

One of my first projects as a professional engineer involved selecting an industrial sensor that could determine the “degree of roast” of coffee beans flying through the roaster. This process uses the SCAA coffee color standards as a metric.

It is important that the system knew how roasted the beans were and that the device was easily accessible by operators on all shifts. I made a couple visits to the actual site of production to map out space constraints and determine the best solution for fixture mounting on the production room floor.

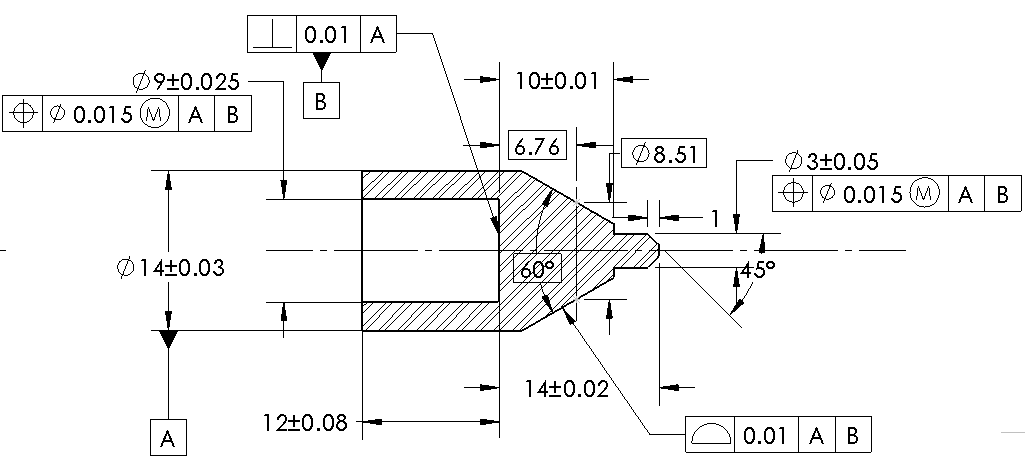

I learned the basics of machine design by creating a movable fixture to hold the sensor. This was also my first project that used Geometric Dimensioning and Tolerancing, a method of exact specification for production of parts.

I really enjoyed diving into the details of GD&T and making sure my machined parts fit together right the first time.