Our Senior Design Team was tasked with creating a device that would remove excess metal powder from metal 3D printed parts (DMLS). This project helped further the varied interests of the University of Pittsburgh/ANSYS Additive Manufacturing Research Laboratory

Metal powders are explosive and can enter the lungs of machine operators. Because of the complex geometry of topology-optimized designs, powder can remain stuck inside the nooks and crannies of lattice structures.

When we started this project, there were few market solutions for powder removal. The ones that are available cost much more than a research team with finite resources would be willing to spend. Our budget for this project was $5000, of which we only used $3000.

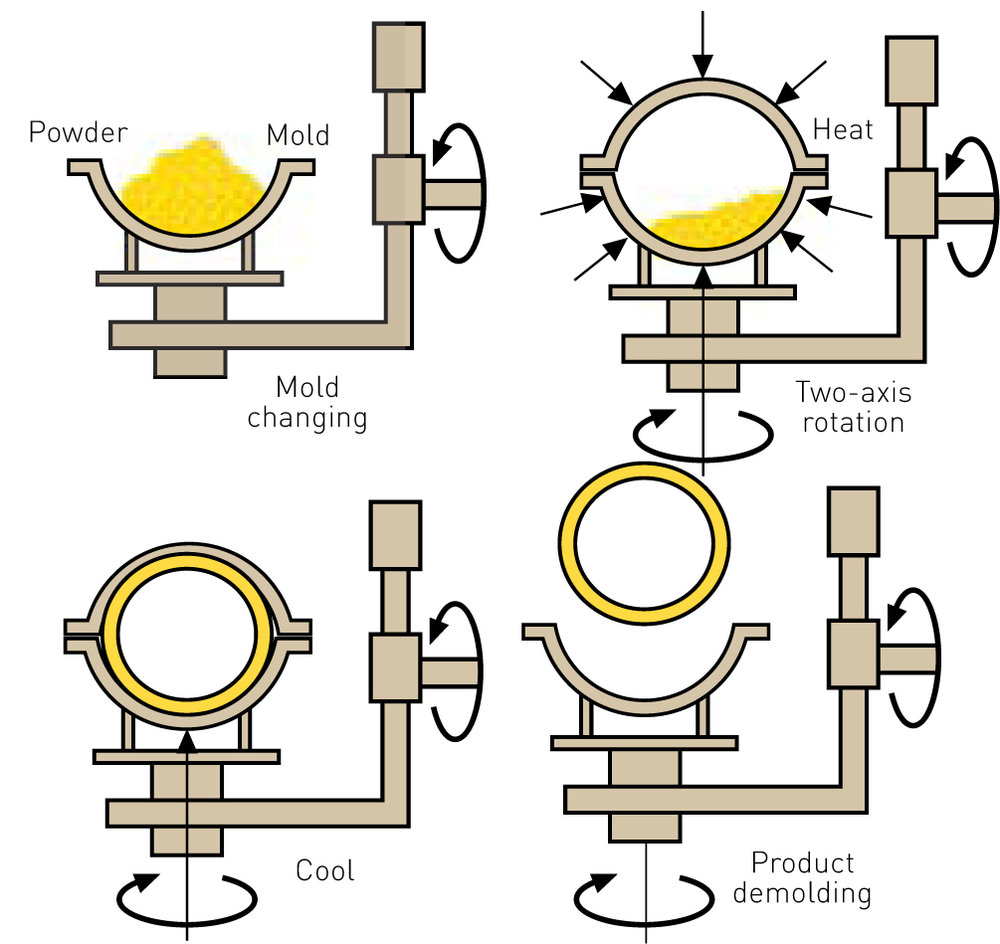

Since cleaning fluids could not be used due to the risk of explosion, we chose to use vibration and rotation as our means of powder removal. Taking inspiration from rotational casting devices that allow for controlled simultaneous rotation in two axes, we built a frame that could hold the weight of a DMLS build plate.

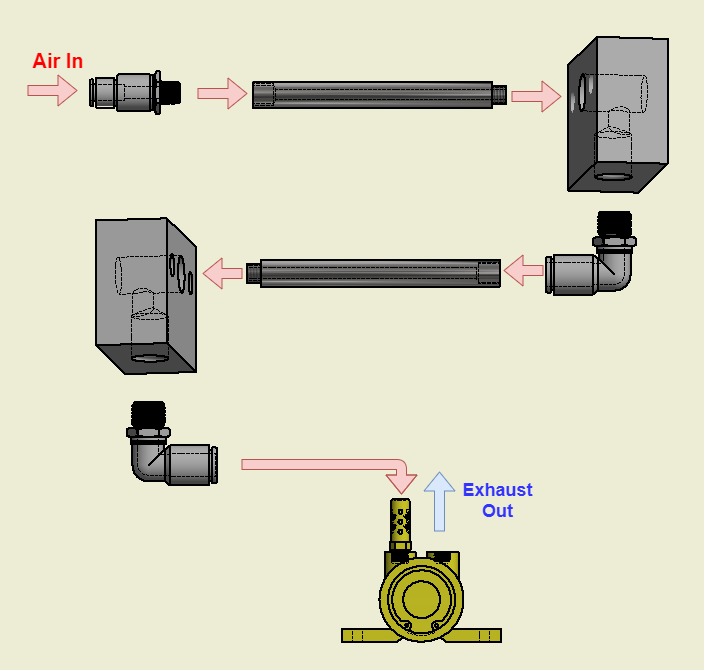

Our biggest challenge was creating an airflow path throughout the machine as it rotated. The pneumatic vibrator needed air to shake the build plate at the desired frequency.

We machined custom shafts and mounting hardware so that air could travel through the system.

Our device ended up winning the Senior Design competition and is still in use today!